Assembly Capabilities

Eurocircuits’ assembly manufacturing capabilities

If PCB is manufactured by Eurocircuits and data has been processed through our PCB Visualizer and PCBA Visualizer, there is the option to transfer the prepared PCBA data to one of Eurocircuits EMS-partners.

Please contact us for more information on our EMS-partners.

Certificates

This section goes deeper into all certificates we have and statements we make towards, RoHS, Reach, Privacy, etc…

All our quality certificates or our production units can be found on the download page.

All manuals, safety instructions and software for our eC-equipment can be found on the download page.

All our specification sheets for base material we use, the soldermask we apply etc. can be found on the download page.

eC-Wiki

Answers to "what does it mean that ..."

This section is still under construction.

Also see our PCB Design Guidelines – Drilled Holes page.

If you have a question, please contact our CHAT support team.

This section is still under construction.

If you have a question, please contact our CHAT support team.

This section is still under construction.

If you have a question, please contact our CHAT support team.

- Current Eurocircuits PCB Design Guidelines

- Download our current PCB classification table

- Download DRU files (Design rules) for CadSoft EAGLE users

- Download the eC-ULP for EAGLE – start the calculation of your PCB price from within EAGLE

- Download templates (EC design rules) for Altium designer users

- What do PCB fabricators do with your data before they make your PCB”s White paper

- The PCB production process explained with short movies

This section is still under construction.

If you have a question, please contact our CHAT support team.

Wim De Greve, head of development for Eurocircuits explains how the PCB Configurator works, and what functionality is available for electronics engineers to configure and visualise their boards before placing an order.

This is a first episode in a series about our smart tools, as presented during a meeting in the Hungarian production plant in January 2018:

- PCB Configurator

- PCB Visualizer

- Classification editor

- Buildup editor

- Outline/Milling editor

Wim De Greve, head of development for Eurocircuits explains how the PCB Configurator works, and what functionality is available for electronics engineers to configure and visualise their boards before placing an order.

This is a first episode in a series about our smart tools, as presented during a meeting in the Hungarian production plant in January 2018:

- PCB Checker

- Plating index

- Drill/Slot editor

- Panel editor

Wim De Greve, head of development for Eurocircuits explains how the PCB Configurator works, and what functionality is available for electronics engineers to configure and visualise their boards before placing an order.

This is a first episode in a series about our smart tools, as presented during a meeting in the Hungarian production plant in January 2018:

- Marking editor

- PCB PIXture editor

- Solder Paste editor

This section is still under construction.

If you have a question, please contact our CHAT support team.

This section is still under construction.

If you have a question, please contact our CHAT support team.

Finance and Administration

Finance and Administration

This section is still under construction.

If you have a question, please contact our CHAT support team.

This section is still under construction.

If you have a question, please contact our CHAT support team.

This section is still under construction.

If you have a question, please contact our CHAT support team.

This section is still under construction.

If you have a question, please contact our CHAT support team.

This section is still under construction.

If you have a question, please contact our CHAT support team.

This section is still under construction.

If you have a question, please contact our CHAT support team.

This is nicely explained on this page.

Getting Started

How to become a Eurocircuits customer and place place your first order.

You can register a Private account or a Business account.

If you or your company are VAT-registered include your VAT number. In many European countries we can then invoice you VAT-free (more).

There is normally no need to pre-pay for your order. We will send you an invoice by email when we have delivered the boards.

On our web site home page, in the right upper corner you will find 2 option to calculate a price.

- FAST price will calculate you a rough idea of price for any quantity of boards, based on standard FR-4 base material and standard PCB technology.

- PCB Calculator will take you to the service selection page where you can find all possible services and specific calculators. Help in making your choice here.

You can make all calculations you want and take benefit of our smart calculator who will validate all chosen technical options for you. So no need to study all our capabilities first, our smart calculator will prevent you from making mistakes.

It is only from the moment that you wish to save your calculation in the shopping basket that you will be asked to login or give your details for registering.

From that moment on you can also profit from our PCB Visualizer and have the software analyse your data (DRC/DFM). Just attach your PCB data to the calculation after login and before you save it to the basket.

Please be in touch with our sales department:

- Chat – on every page of our transaction web site you can activate the online chat button. You will see us online during office hours. You may also use this communication to leave your message while we are offline. It is efficient as we can see where in the web site you are and who you are, so we can help you faster.

- E-mail – euro@eurocircuits.com

- Tf – +32 15 28 16 30 for the Belgian main office. For local offices look here.

YES.

To use any of our services, enter the board details into the online Price calculator and calculate the price. Attach the data and put the order in your basket (you can use PCB Visualizer to check all details and view your PCB already).

Proceed to checkout and you will be asked for your (company) name, address etc. You can register a Private account or a Business account. If you or your company are VAT-registered include your VAT number. In many European countries we can then invoice you VAT-free (more).

Place your order. We will check the details provided while our engineers are checking your data.

If everything is OK, we will open a QuickStart credit account for you and proceed with your order without delay.

You don’t have to pay up-front. We will invoice you when the goods are shipped.

Customer feedback:

I’m using Internet explore 8.0.6001… on a Windows XP 32bit PC. I get the message that I need a more recent version of my browser.

PCB Visualizer support reaction:

PCB Visualizer is using HTML5 code. This code is not supported by older versions of Internet Explorer. In Windows XP you cannot upgrade to version 9 or 10 of Windows Explorer, so the only solution is to try another browser.

We suggest Firefox or Google Chrome, these are the most common browsers used by our customers (based on our google analytics data), and we most actively debug PCB Visualizer on these two browsers.

The fastest delivery term depends on the chosen service and even more on the chosen technology.

The fastest we offer is 1 working day in our NAKED proto service covering 1 and 2 layer boards without solder mask or legend and in quantities of 1, 2 or 5 PCBs.

What do you need?

First you should decide for the base material to be used for your PCBs. FR-4 is the standard base material but we can also offer other material for specific application which are plced under special base materials.

FR-4 (standard base material) pooling services

- NAKED proto – basic prototype pooling service. Quick & dirty.

1, 2 or 5 boards 1 or 2 layers without solder mask in 1 to 7 working days - PCB proto – dedicated prototype pooling service.

1, 2 or 5 boards 2 or 4 layers standard PCB technology in 2 to 7 working days - STANDARD pool – widest range of pooled and non pooled options up to 16 layers

Other TG values, finer layout, more layers, higher quantity, etc… - BINDI pool – Eurocircuits’ Asian alternative with European assured quality.

2 and 4 layer boards with standard technology in medium quantities at Indian cost but inhouse produced in India.

Special base material pooling services

- RF pool – Isola I-TERA and Rogers 4000 series materials

For RF specialists that need their specific base material but at lower pooling costing - SEMI-FLEX pool – flex-to-install flex-rigid pooling service.

Something brand new to replace rigid -flex boards in flex-to-install applications and at pooling prices for our 4 layer offer. - IMS pool – Insulated Metal Substrate PCBs

Need aluminium-backed boards for cooling purposes. Prototypes and small series at acceptable prices due to pooling conditions.

You cannot find what you are looking for here?

Please be in touch with our sales department:

- Chat – on every page of our transaction web site you can activate the online chat button. You will see us online during office hours. You may also use this communication to leave your message while we are offline. It is efficient as we can see where in the web site you are and who you are, so we can help you faster.

- E-mail – euro@eurocircuits.com

- Tf – +32 15 28 16 30 for the Belgian main office. For local offices look here.

How to ?

How to answers questions to do things “right first time”.

Log in to your customer account on our web site (or create an account), then upload your data into the PCB Visualizer and check the data using the PCB Configurator and PCB Checker.

Please follow the link below for our guidelines on how to create and order a customer panel.

Guidelines for customers that design and upload their own panel data

Once your data is uploaded to the Eurocircuits PCB Visualizer you able to select the Stencil section of the PCB Configurator and choose Top, Bottom or Both Stencils.

You are also able to edit your Solder Paste data using our New Solder Paste Editor in the PCB Checker tab.

The build-up of the PCB is usually predefined when you upload you data files to the Eurocircuits PCB Visualizer. If this is not possible or you need an alternative build you can use our Buildup Editor in the PCB Configurator. Here you can select from our predefined builds or if necessary request a special build.

Please follow the link below for more information.

PCB Designrichtlinien – Mechanische Lagen.

These may increase the cost of the PCB

You can add all types of markings including UL using the Eurocircuits Marking Editor, follow the link below for instructions.

Eurocircuits Tips & Tricks – Marking Editor

These may increase the cost of the PCB.

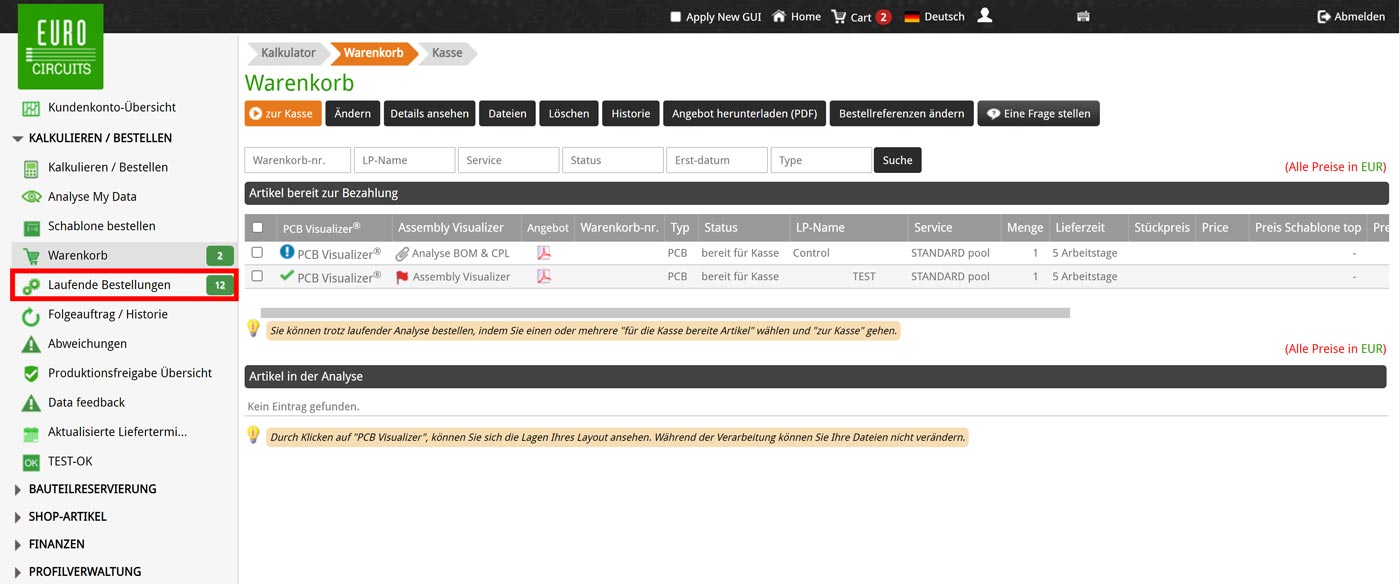

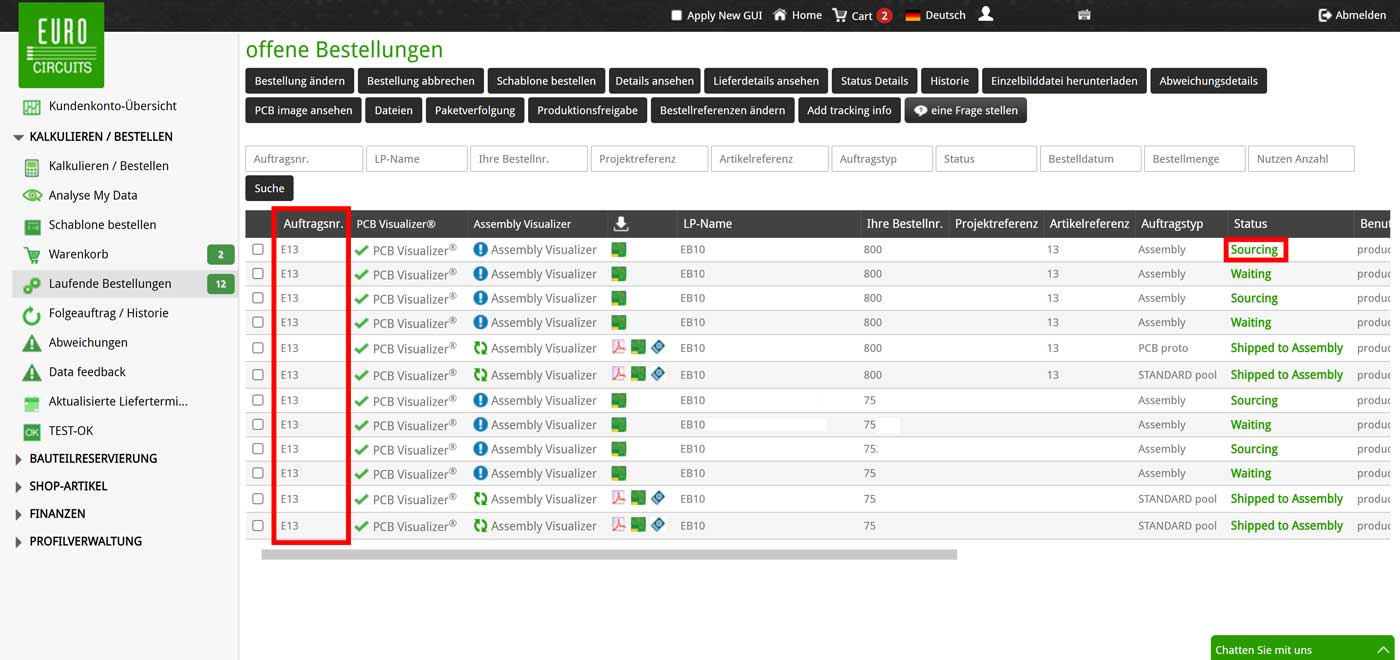

Schritt 1: Gehen Sie zu Ihrem Online-Kundenkonto und klicken Sie auf “Laufende Bestellungen”.

In dieser Übersicht sehen Sie drei verschiedene Typen der gleichen Auftragsbestellung.

- Ihre Leiterplattenbestellung (7-stellige E-Nummer)

- Ihr Bestückauftrag (E-Nummer, die auf A endet)

- Ihre Bauteilebestellung (E-Nummer, die auf B endet)

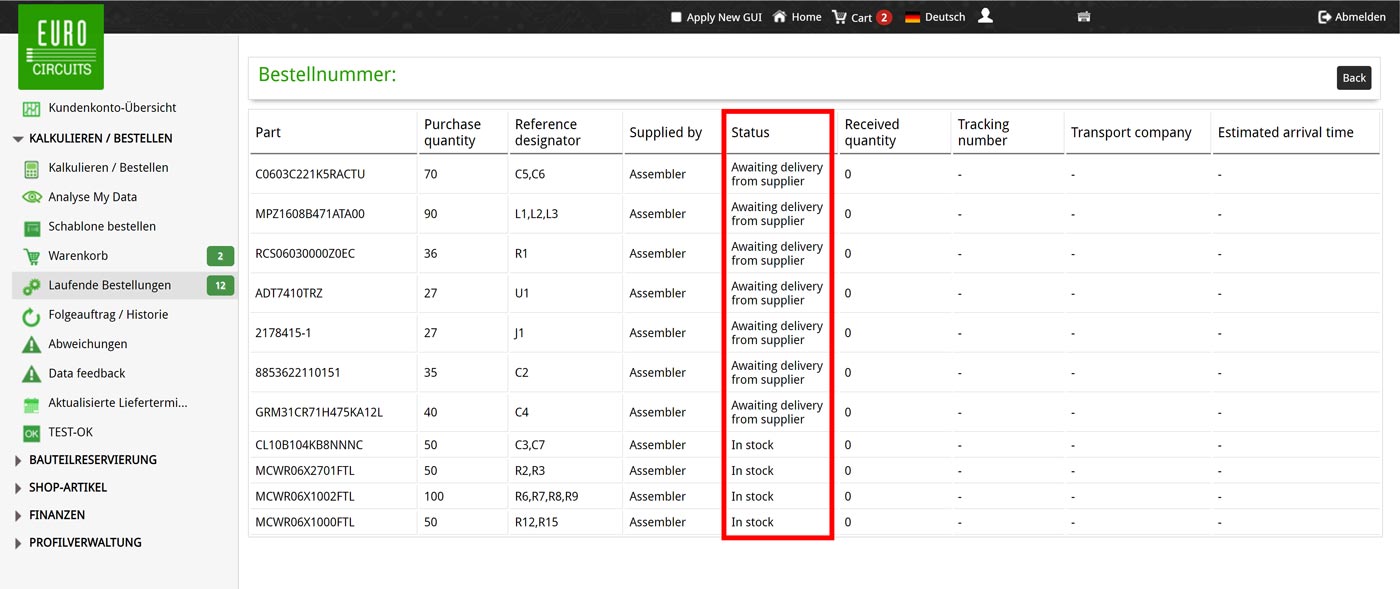

Schritt 2: Klicken Sie auf den Status Ihrer Bauteilebestellung

Schritt 3: Sehen Sie sich den Status jedes Bauteils an, um die Bauteileverfügbarkeit von jedem Auftrag zu überwachen

Mögliche Status:

- vorrätig

- Warten auf Lieferung vom Bauteilelieferanten

- Warten auf Lieferung vom Kunden

- Teilweise vom Kunden geliefert (Wenn Eurocircuits nur einen Teil der Bauteile erhält, die zur Fertigstellung des Auftrags benötigt werden)

Hinweis

Wenn Ihr Bestückungsauftrag gefertigt werden soll und nur ein Teil der Komponenten zur Verfügung steht, wenden Sie sich bitte an unseren Kundendienst.

Order and Delivery

Questions related to the logistics.

Changing the delivery address for a running order is possible until the status of the order says “Production Finish”. How to do this?

- Go to “’running orders”

- Select the order and click the black button “modify order”

- Click “change delivery address”

- In the next window: select a different delivery address from the drop down list

If you want to ship to an address, which is not yet appearing in this dropdown list, please contact the power user of the account. He can create a new delivery address in this dropdown list. (He can do this via “manage profile”).

This depends of the status of your order.

If the preparation of the data is already finished or if the order is in production, no changes are possible anymore.

The fastest way to make the modification is through your online account:

- Go to your “running order” list.

- Select the order by checking the box on the left.

- Click the black button “modify order” on top of the page (Important tip: don’t do this by clicking on the PCB Visualizer, no changes can be saved via PCB Visualizer for a running order !).

- The system will tell you if the order can still be modified.

- If possible (after clicking on “modify specifications”) this order will automatically be “cancelled” and will be placed back in your shopping basket. (Important: the order is not processing anymore)

- In your shopping basket, you can then modify the order details, delivery term and/or upload a new dataset using PCB Visualizer if you like

- Check out the item again to re-order and verify if it re-appears now in your list of “running orders”. If it does, it will have a new order number and you will be sure it is back in process.

There are two cases that might require new PCB data to be uploaded or sent:

- The order is in “exception overview”. You can upload a new dataset via “view details” and using the button “modify”.

The instructions are also given in the exception document which you can download to review all data issues. - The order is in “preproduction approval”. You can only solve the data issues by delivering a new PCB dataset thus you must reject the Eurocircuits proposed solution. Proceed as follows:

- Reject the approval and explain in the message that you will send new data and why. Then send us the data right away and we will upload them for you.

- Need more time to redesign? Then we will move the order to “exception overview”. From there you can change many parameters and upload a new PCB dataset when ready. The delivery term will be recalculated as soon as the modification and data upload is done.

See also: what happens if there is a problem with my data?

This section is still under construction.

If you have a question, please contact our CHAT support team.

You can add or change the purchase reference for an item in your shopping basket or for a running order until the status of the order says “Production Finish”. How to do this?

- Go to your shopping basket or to the list of your running orders

- Select the item or order and click the black button “edit administrative details”.

- Now you can add your references.

It is important that these fields are activated to be shown in your account (sometimes they are hidden). If only the PCB name appears, please contact the power user of the account. He can activate these fields. (He can do this via “manage profile”).

This section is still under construction.

If you have a question, please contact our CHAT support team.

This section is still under construction.

If you have a question, please contact our CHAT support team.

This section is still under construction.

If you have a question, please contact our CHAT support team.

Ja, Sie können die Produktionsdaten überprüfen, bevor wir mit der Fertigung starten.

Wenn Sie die Daten, die für die Produktion Ihres Auftrags verwendet werden sollen, prüfen und genehmigen möchten, müssen Sie eine Produktionsfreigabe (Pre-Production Approval, PPA) für den jeweiligen Auftrag, den Sie überprüfen möchten, anfordern.

Sie werden dann gebeten, die Daten zu genehmigen, die für die Fertigung Ihrer Leiterplatten verwendet werden, bevor wir mit der Produktion beginnen.

Sobald unsere Ingenieure ihre Prüfungen abgeschlossen haben, senden wir Ihnen eine E-Mail, in der wir Ihnen mitteilen, dass die Produktionsdateien fertig sind und auf Ihre Freigabe warten.

Freigabe vor der Produktion festlegen

Eine PPA können Sie an der Kasse anfordern. Markieren Sie das Feld „Dieses Feld aktivieren, wenn Sie eine Produktionsfreigabe (PPA) möchten“ unter der Schaltfläche Absenden.

Wenn Sie die Bestellung aufgegeben haben, können Sie alternativ eine Produktionsfreigabe anfordern, indem Sie die Bestellung in Ihrem Eurocircuits-Kundenkonto unter Laufende Aufträge auswählen. Klicken Sie dann oben auf die Registerkarte Produktionsfreigabe anfordern.

ACHTUNG

- Das Anfordern der PPA ist nicht mehr möglich, wenn sich der Auftrag im Status “Panelise/Nutzen erstellt” befindet. Wenn der Fertigungsnutzen fertig ist, ist es für die Produktionsfreigabe zu spät.

Sobald die Datenaufbereitung abgeschlossen ist, erhalten Sie eine E-Mail mit der Bitte um Rückmeldung, ob Sie mit dem Bestellprozess fortfahren möchten.

Dies geschieht mit unserem Daten-Feedback-Prozess, bei dem Sie die vorgeschlagenen Daten überprüfen, akzeptieren oder ablehnen können.

Siehe auch:

Tipps und Tricks für korrekte Fertigungungsdaten im PCB-Design

We have always run 100% pre-production checks on customer data. That way we can be sure you will get the board you want on the day you want it.

Our online check software, PCB Visualizer, has significantly reduced the number of exceptions but there may be remaining data or order issues.

Our engineers use their know-how to make the most logical correction to the order or the data where possible. This results into two possibilities:

- Logical corrections by our people are possible and we only need customer approval:

The production-ready job goes into the customer’s pre-production approval (PPA) folder. He gets our email and needs only 1 click to send the job on for manufacture. How?- Go to “preproduction approval” – the status of your order is “waiting for your approval”.

- Click the orange button “review for approval” – the document with the repair details/proposal/corrections will open automatically on your screen (if not, click on the grey button “repair details” to open it).

- Check our proposed “repairs” in the document.

- Have a closer look in PCB Visualizer: our production data of your PCB or customer panel (including the repairs) is displayed on your screen (especially check technical options like internal milling, customer panel layout and other specifics).

- Then you decide to “approve” or “reject”:

- If approved, the order will be moved directly to our production panel section, no changes are possible after that.

- If rejected, do the following of two options:

- write clearly why in the comments section and our people will receive your message and will check how to proceed next

- or upload a new data set after which your order is processed further through the exception flow

Nearly 90% of jobs are authorised right away and go straight into production. No delays – and the customer doesn’t have to spend time making the corrections – a win-win result: the right board on the right day with minimum disruption to the designer.

- A logical correction was not possible and we need the customers input:

- If the detected PCB data issue is not “repairable” by Eurocircuits and no solution can be proposed, then we will raise an “exception” as we have always done.

- Go online to “exception overview” – check the problem, correct your data and upload your new complete PCB dataset.

- The delivery date will be recalculated at the moment when you upload your dataset. Do this as fast as possible to avoid any delay in delivery.

The cut-off time for placing an order is 24H00, meaning that the delivery term starts at 00H00 of the next day.

This section is still under construction.

If you have a question, please contact our CHAT support team.

Yes, a final order confirmation is sent after the preparation of your PCB data is done and the data are ready for production.

In case you have asked for a pre-production approval, we will send the order confirmation after your final approval to move ahead in to production.

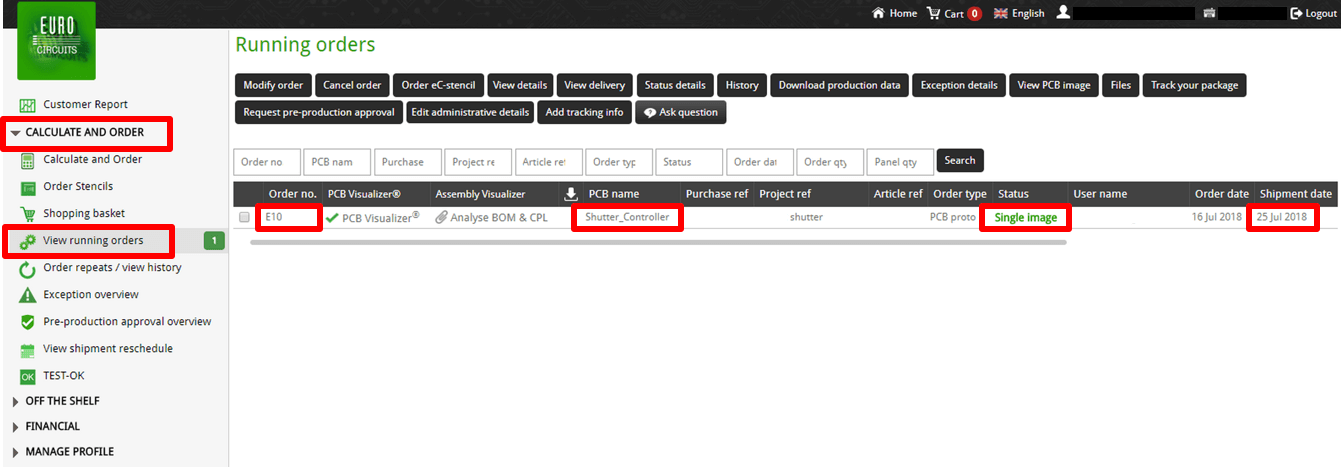

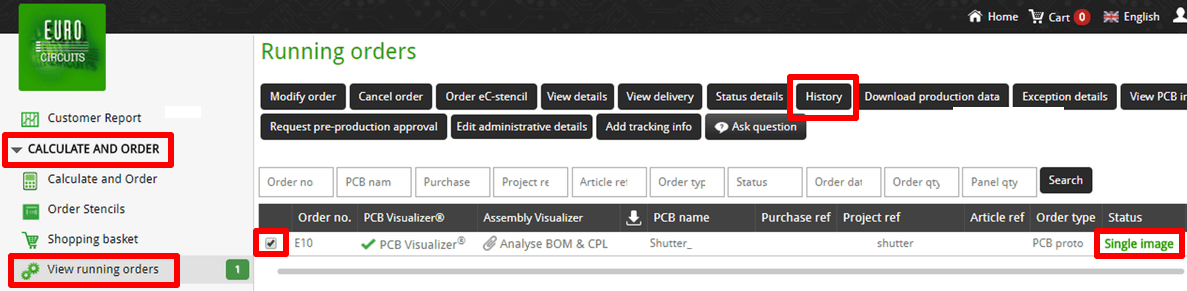

Um den Status Ihrer Bestellung zu verfolgen, melden Sie sich zunächst mit Ihrem Eurocircuits-Konto an.

Wählen Sie aus dem Menü auf der linken Seite “KALKULIEREN/BESTELLEN” und dann “Laufende Bestellungen anzeigen”.

Daraufhin öffnet sich ein Fenster mit einer Liste aller Ihrer laufenden Aufträge und Informationen wie z.B. Auftragsnummer, Leiterplattenname, Auftragsstatus und erwartetes Versanddatum.

Um den Status Ihrer Bestellung zu überprüfen, markieren Sie zunächst das Kästchen neben der Bestellnummer und wählen dann entweder die Schaltfläche “Historie” am oberen Rand des Fensters oder klicken direkt auf den Status in der Bestellzeile.

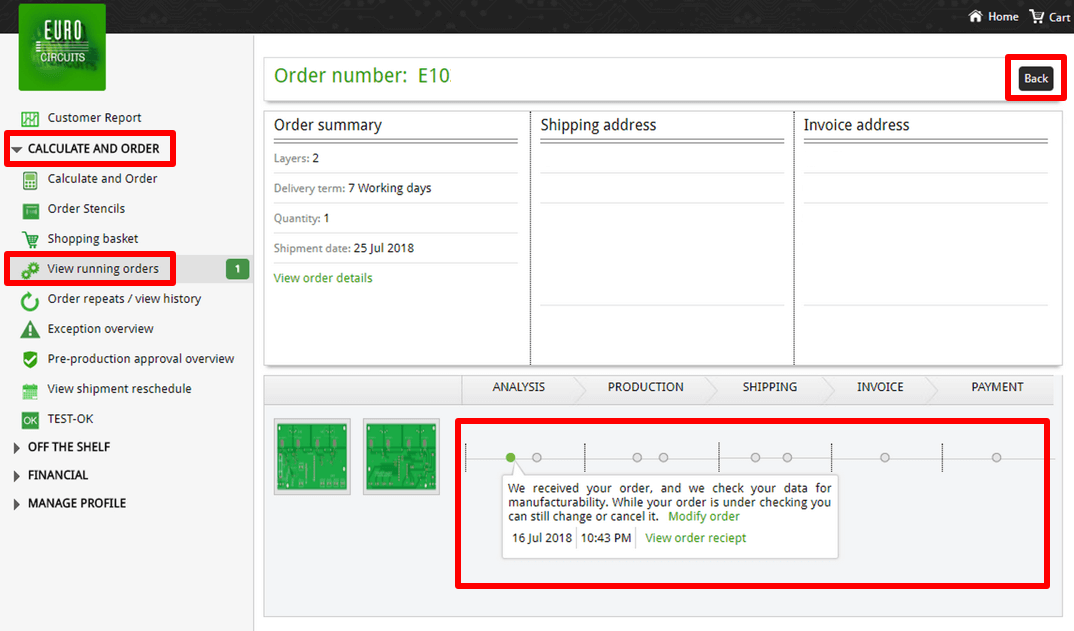

Es öffnet sich ein Pop-up-Fenster, in dem Sie den Status Ihrer Bestellung sehen können. Wählen Sie die Schaltfläche “Zurück”, um zur Übersicht “Laufende Aufträge” zurückzukehren.

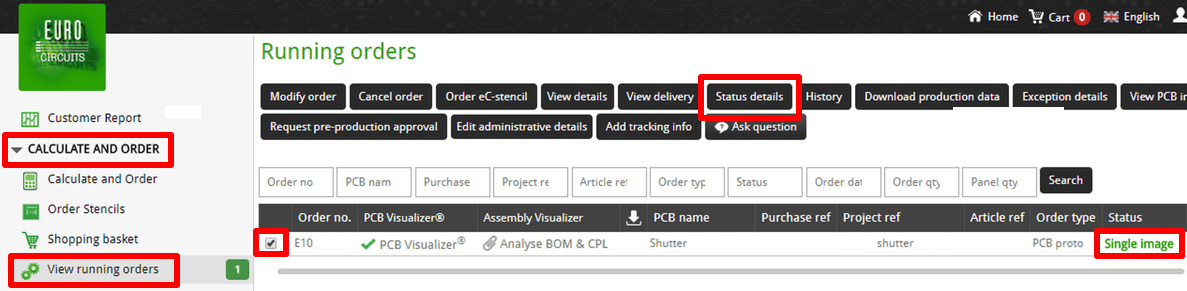

Für eine Definition des Textes in der Spalte “Status” wählen Sie die Schaltfläche “Statusdetails” am oberen Rand des Fensters.

Nun öffnet sich ein Pop-up-Fenster, in dem alle Erklärungen der Begriffe angezeigt werden.

PCB Capabilities

Eurocircuits’ PCB manufacturing capabilities

Eurocircuits are able to manufacture Blind and Buried Via’s, however, we suggest you read our technical articles and Blog before adding these to your PCB layout, follow the links below:

Blog – Blind and buried Via’s

Technical Article – Blind and buried Via

Eurocircuits offers SEMI-Flex Production, please follow the link below for more information:

For every PCB/Panel manufactured by Eurocircuits generate a PCB Passport, this details the materials, Production steps and Test Results etc.

More information can be found by following the link below:

Eurocircuits does offer these services, we recommend that you read our Blog on this topic by following the link below:

Please follow the link below to see the Quality Labels held for each facility.

Please follow the link below for our non-BINDI Pool production:

Technical Specifications of all Eurocircuits Prototype & small volume

Please follow the link below for our BINDI Pool production

Our PCB Services and capabilities are available by following the link below:

You are able to find the specifications for the materials we use by following the link below: