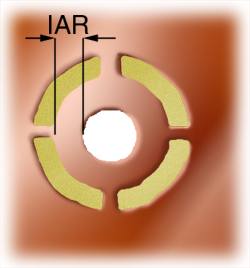

IAR (Innenlagenrestring = 1/2 (Paddurchmesser Innenlage – Werkzeugdurchmesser))

IAR (Innenlagenrestring = 1/2 (Paddurchmesser Innenlage – Werkzeugdurchmesser))

Beispiel:

Berechnung Restring : IAR = (Paddurchmesser – WERKZEUGDURCHMESSER)/2

WERKZEUGDURCHMESSER = ENDDURCHMESSER + 0.10mm für alle PTH-Bohrungen + 0.00mm für alle NPTH-Bohrungen

Berechnung IAR für ein Pad mit 0.60mm Durchmesser und einem Enddurchmesser von 0.25mm(PTH):

IAR = (0.60mm – (0.25mm + 0.10mm))/2

= (0.60mm – 0.35mm)/2

= 0.250mm/2

= 0.125mm

Dies entspricht unserer Leiterbildklasse 6 unserem Standard für Pooling Service .

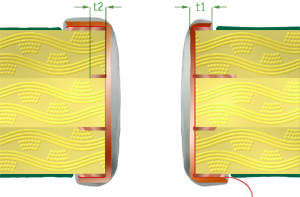

FAR (Finished Annular Ring).

Ist der Bereich der äußeren Padkante und der Bohrung. Infolge der mehr oder weniger zentrischen Bohrung kann dieser Ring unterbrochen sein. Abhängig vom Paddurchmesser und des Nominaldurchmessers der Bohrung

- Die Breite (t1) des Restrings auf Außenlagen muss min. >= 0,050 mm auf der fertigen Leiterplatte sein.

- Die Breite (t2) des Restrings auf Innenlagen muss min. >= 0,100 mm auf der fertigen Leiterplatte sein.