- The minimum distance between any two V-cut lines is 5.00 mm

- Panels with V-cut do not necessarily need a panel border to create mechanical stability. The panel border on V-cut panels is mainly for ease of handling during the assembly process ( tooling holes, fiducials)

- eC-registration compatible panels need a border to host the positioning holes

- V-cut is always over the complete length of the panel ( no jump-scoring) This means that only square or rectangular PCB’s of the same size can be panelized when V-cut is the only board separation method chosen.

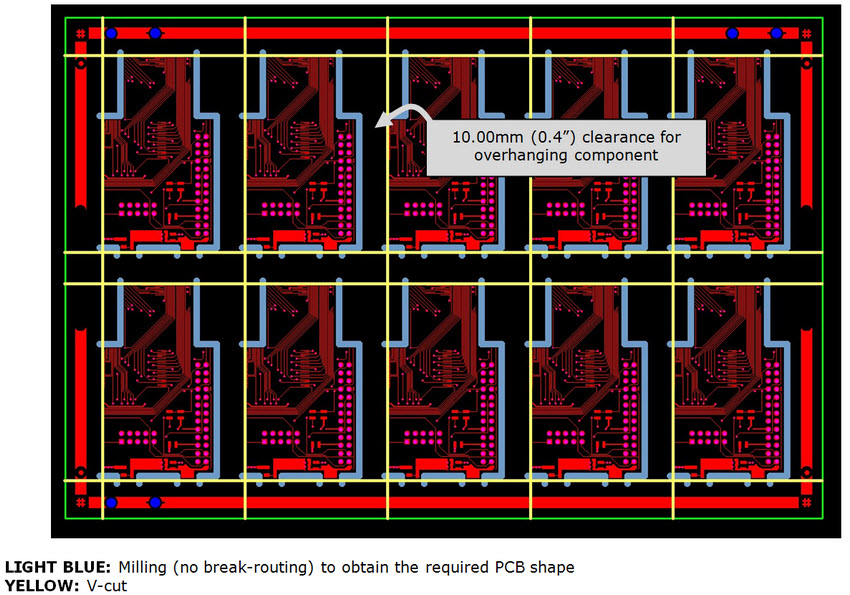

- It is however possible to use V-cut on irregular shaped PCB’s when used in combination with extra milling or even break-routing to obtain the desired PCB shape. In such cases you may need to add extra clearance between the PCB’s to provide “run-out” space for the milling or break-out-router.

- See the following example of a panel with a combination of V-cut with extra milling: